A New Era in Critical Minerals Refining

Introducing the Future of Nickel, Cobalt, and Lithium Refining

Precision Periodic is revolutionizing the refining of nickel, cobalt, and lithium with a game-changing process designed to transform the landscape of critical minerals production, delivering unparalleled simplicity, speed, and cost-effectiveness. Supported by a grant from the Department of Energy (DOE), we have developed and are now deploying an innovative refining solution where efficiency meets sustainability, setting a new standard for the industry. Our groundbreaking Nano Beads filtration media redefines the purification process for nickel, cobalt, and lithium, achieving minimal loss while delivering better-than-battery-grade purity in minutes. Read on to explore how we are transforming the landscape of critical minerals refining with our revolutionary approach.

Redefining Refining

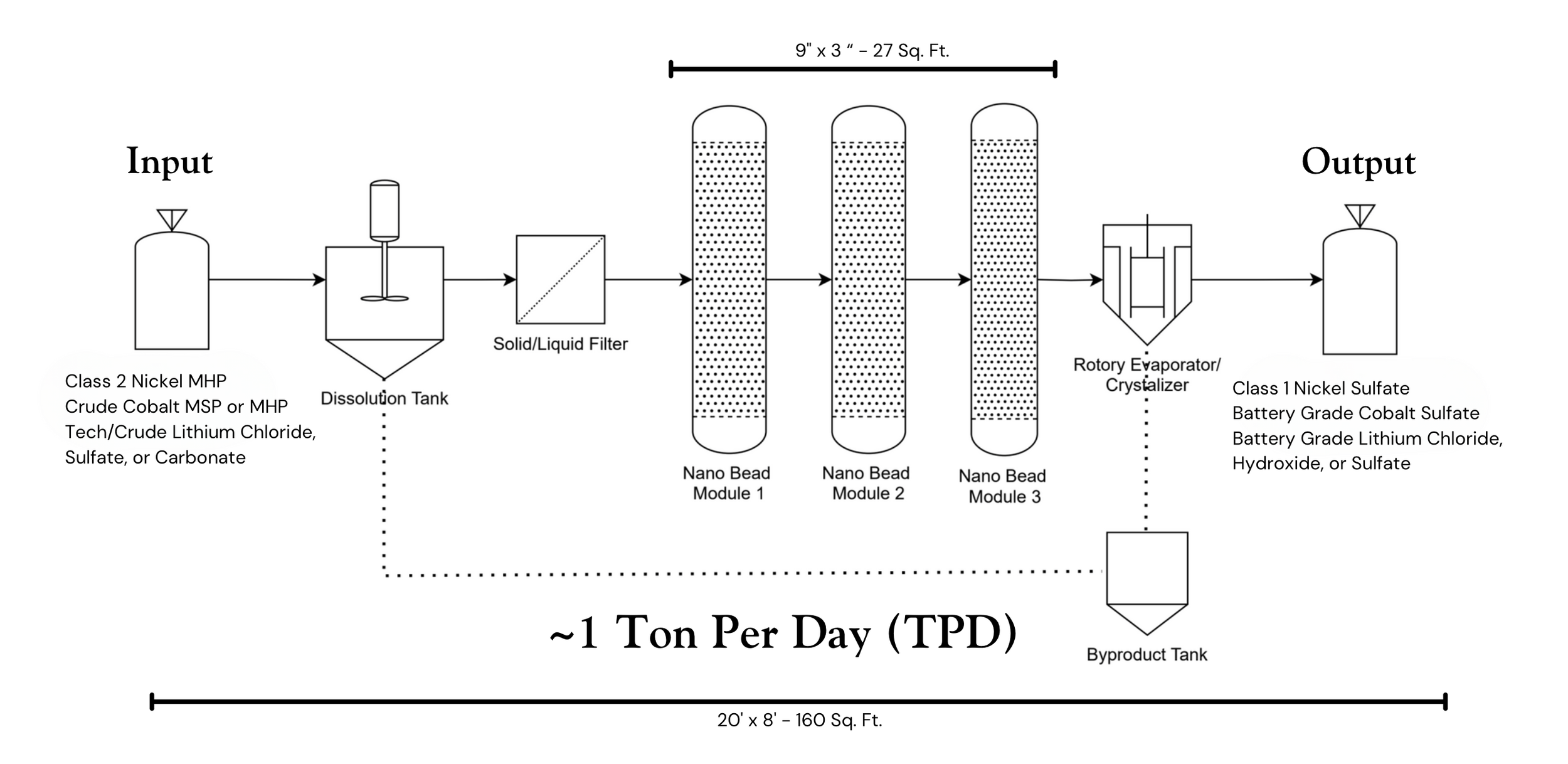

Precision Periodic’s sustainable, scalable, and low-cost process leverages our proprietary Nano Beads sorbent technology to refine multiple metals into battery-grade purity, using the same plant equipment and process compared to traditional methods, while enabling modular, plug-n-play expansion to meet growing demand at a fraction of the cost.

Nano Bead Module

Revolutionizing metal refining by enabling a single, versatile plant to process critical materials—nickel, cobalt, lithium—into battery-grade purity. Our cutting-edge process minimizes waste and water usage and scales effortlessly to grow with market demand, redefining efficiency and sustainability in the critical materials supply chain.

Refine Nickel, Cobalt, and/or Lithium

Each Multi-Scale Refining Unit (MSRU) can process nickel, cobalt, or lithium as desired, offering unparalleled flexibility to meet specific production goals. Powered by our proprietary Nano Beads filtration media, each unit can seamlessly switch between refining nickel Mixed Hydroxide Precipitate (MHP) into Class 1 nickel, purifying cobalt to battery-grade standards, or producing high-purity lithium compounds like lithium hydroxide (LiOH), all within the same modular system. This adaptability ensures that our technology can respond to market demands in real time, delivering better-than-battery-grade purity for any of the three minerals with minimal loss and maximum efficiency, while maintaining a sustainable, low-impact operation.

Multi-Scale Refining Unit

Our Multi-Scale Refining Unit (MSRU) is designed to occupy just 160 square feet, equivalent to the footprint of a standard 20-foot by 8-foot shipping container, making it remarkably space-efficient and ideal for deployment in a variety of locations with limited space. This compact size allows for easy integration into existing facilities, urban industrial sites, or even remote mining operations, requiring no extensive land preparation or large-scale infrastructure, and is powered with standard building-provided power, eliminating the need for specialized electrical setups. Furthermore, our innovative process eliminates the regulatory approvals typically required for traditional refineries, streamlining deployment and reducing both time and financial barriers, allowing to scale production efficiently while maintaining operational agility.

-

Unmatched Efficiency

Our refining process achieves unmatched efficiency by enabling rapid, high-purity production of battery-grade nickel, cobalt, and lithium in minutes, with minimal loss. The Nano Beads’ high selectivity ensures precise extraction of target minerals, reducing waste and eliminating the need for energy-intensive steps common in traditional refining methods,

-

Universalability

The modular MSRU (Multi-Scale Refining Unit) streamlines operations by processing any of the three minerals within the same system, cutting downtime and operational complexity. This low-energy, low-water approach not only accelerates production but also slashes costs, all while minimizing environmental impact through reduced resource consumption and waste output, setting a new standard for sustainable, cost-effective refining.

-

Sustainable & Cost-Effective

With a focus on minimizing environmental impact, our refining process for nickel, cobalt, and lithium uses less water, reduces chemical waste, and lowers energy consumption, ensuring a greener operation. Economically, it slashes production costs by eliminating the need for acid and caustic reagents, making the refining of these critical minerals not only more sustainable but also significantly more cost-effective.

-

High Purity Output

Our technology guarantees battery-grade nickel, cobalt, and lithium that surpass traditional specifications, ensuring that electric vehicle batteries, renewable energy storage systems, and other high-demand applications perform at their peak with longer life cycles, higher efficiency, and enhanced reliability.